Industrial waste treatment plant combining EnerTwin and heatpump

RGS Nordic combined the existing heatpump with the complimentary EnerTwin, enhancing the efficiency of both. The reliability was instrumental to the implementation due to the continuous separation process.

Context

RGS Nordic operates various waste-water treatment plants and specializes further in the treatment of contaminated soil and construction materials. Companies are increasingly faced with CSR and environmental challenges by customers as well as shareholders and local authorities.

Clients vision: “We want to offer our children a world where the Earth’s resources are cleaned and recycled”.

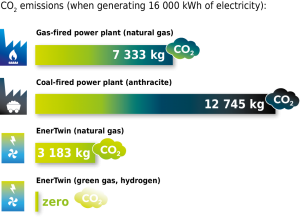

Reduction of the company carbon footprint (both CO2 and NOx emissions) compliments the services offered to their customers and is therefore dominant on clients agenda.

The Use Case

- RGS Nordic, Slop oil separation plant

- Location: Skælskør, Denmark

- The EnerTwin replaced a old heating oil fired boiler and is put in cascade with a heat pump for optimum efficiency. This way, 2 major goals have been achieved:

- Slop oil separation capacity has increased towards 8.000 to 10.000 m3/year, to meet increased demand;

- Pay back of full installation (heat pump + EnerTwin) within 2.4 years, due to higher efficiency and electricity production

- Substantial lower CO2 and NOx emissions. Based on estimated running hours (6.000+ p.a.) and cleaner fuels, more then 10 tonnes of CO2 emissions are avoided each year.

The role of the EnerTwin

MTT’s client RGS Nordic A/S receives approximately 4.000 to 6.000 cubic meters of slop oil each year. Slop oil is a mixture of oil and water. The separation process is improved by adding heat.

Factual results of the project

- Installation performed by the Danish EnerTwin dealer HC Energy

- Annual running hours: 6500 hrs

- Slop oil separation capacity has increased towards 8.000 to 10.000 m3/year, to meet increased demand;

- Combination adds 40% efficiency to the existing heatpump

- Reliable heating solution for separation process

- ROI to be achieved without any subvention

- Climate goals have been achieved with CO₂ and NOₓ emissions reduced by 9,5 Tons a year

- Plug&Play installation with little impact on operations of the company

“Soft” results of the project, the HC Energy feedback:

- The EnerTwin was taken into operation in September 2020. After a thorough evaluation client decided to extend the system with another EnerTwin unit, which is expected to go into operation in Q2 2021.

- The results that surfaced after the first year of operation regarding CO2 reduction based on the runhours were impressive. The seamless combination with the heatpump improved efficiency of both systems.

- Client was positively surprised by the impact on the end-users and ease of implementation, considering application in the office buildings in their portfolio.

- HC Energy was impressed with the ease of doing business plus training & support from MTT’s service department.