Voormalige stallen verbouwd tot kantoorgebouw

EnerTwin geïnstalleerd in combinatie met een grotere ketel, in een gemeenschappelijke stookruimte voor een kantoorgebouw van 3 verdiepingen.

The EnerTwin was implemented to cover new energy-demand and sustainability goals in a cost-efficient way. Costly adjustment to the building structure to accommodate low-temperature heating systems were avoided. With >5000 runhours per year a great return on investment was achieved.

Context

According to the Energy Performance of Building Directive (EPBD, Europe), Commercial office buildings require energy label improvement. This applies to all existing office buildings. Monuments and historic heritage are exempt from the implementation of EPBD.

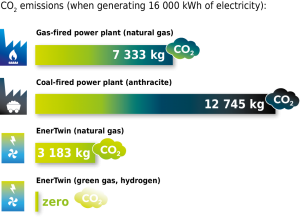

Companies are increasingly faced with CSR and environmental challenges by customers as well as shareholders and local authorities. Reduction of the company carbon footprint (both CO2 and NOx emissions) is on management agendas.

The Use Case

- Historic Office Building Dresden

- Location: former stables refurbished to office-building, Dresden, Germany

- The management formed a project team charged with finding the best fitting solution for the identified challenge and thereby involving the local operational team in the project

- The challenge was initiated by replacement of a traditional condensing boiler due to age. With the implementation of EPBD for this building coming up, combined with the sustainability plan of the company a more radical change was due. The company required strong improvement of the energy-performance and together with the building owner, various options were investigated. Silent operation, as the unit would be operating in the proximity of the office staff, was mandatory. Engine-based CHP systems were therefore found unsuitable. The building would also not allow for costly changes for low-temperature systems that are required by other systems such as heatpumps or fuel-cells.

- The company expected strong changes in the energetic sector driving towards sustainability and required a product that was adaptive to future developments like green gas and hydrogen mixes.

- Installation: EnerTwin is connected to the heating circuit through a buffer tank.

- Annual estimated running hours: 5000+ hrs.

The role of the EnerTwin

The EnerTwin is installed in a shared heating room for a 3 level office building, formerly in use as a stable building. In this set-up, the EnerTwin is connected to a buffer vessel, which itself is connected to the main heating circuit of the building.

Factual results of the project

- Installation: Installation costs totaled at € 3500

- Annual running hours: 5000+ hrs

- Electricity produced: 11250 kWh

- Existing condensing boilers used for peakloads

- Reliable heating solution covering 90% of heatload

- Subventions according to BAFA have been granted

- Reduction of energy bill at 105% of planned

- Climate goals have been achieved with CO₂ and NOₓ emissions reduced by 9,5 Tons a year

- Silent operation, inaudible for office staff

- Plug&Play installation with little impact on operations of the company

“Soft” results of the project, the projectteam feedback:

- Sustainability goals for both the developer and end-users were considered an import step into the future of the company. Providing electrical energy for office-use whilst the building was heated by the EnerTwin at high efficiency was a very satisfying concept for the team.

- The results that surfaced after the first year of operation regarding CO2 reduction based on the runhours were impressive. By installing a buffervessel, the runhours created more continuous operation and more runhours.

- Management reported better than expected financial results due to the overshoot in runhours.

- The building-owner was positively surprised by the impact on the end-users and ease of implementation, considering application in other commercial real-estate in their portfolio.